The port industry has a history of innovating to meet the changing requirements of global shipping and trade – from the mechanization of port equipment in the first industrial revolution all the way to the fully connected smart ports emerging today. With each wave of innovation, the interaction between operator and port cranes has evolved as well, and with it the way in which operators need to be trained and prepared to perform their tasks efficiently and safely. Over the past two decades or so, rapid development in computing power and visualization technology have enabled simulator-based training to emerge as a cost-efficient and safe way to train port crane and equipment operators.

However, as cranes are becoming smarter and ports are becoming more digitized, how do you ensure that your simulation-based training reflects the capabilities and technology of the modern terminal and doesn’t risk becoming a disconnected island within your port? Let’s have a look at some of the major trends in the port industry and their impact on operator training.

Productivity & Efficiency

As ship sizes increase, so do peaks in port crane capacity needed to handle their cargo. With only an estimated 5% of global terminals expected to be fully automated by 2020, this means that port productivity heavily relies on the availability of qualified operators and crane types to increase moves per hour.

The ROI case for using simulators to train operators has been widely published and it is estimated that simulators can decrease time to task proficiency by up to 90%. Productivity gains from simulator training include increasing the number of moves per session and freeing up productive crane capacity otherwise tied up in training. Simulators can also be used for pre-training assessments, pro-active and reactive reassessment and certifying operators on new crane types.

The advantages of simulator-based training increase dramatically with the accuracy of the simulation. Training operators on a system that realistically duplicates the appearance and feel of the crane, the load and the interaction with the virtual environment is a critical factor in the overall effectiveness of simulator-based training.

In order to achieve this, the simulator has to be able to accurately replicate the behaviour and use of the physical crane and all of its subsystems (e.g. mechanics, rope systems and power train) in real-time.

Safety

As global safety standards in the shipping and port industries are raised, it is important to not only train your crews and operators on the safe handling of cargo but also prepare them for dangerous or extreme situations such as crane malfunction or weather events. Simulators provide a cost-efficient, repeatable and safe way to familiarize operators with these circumstances. The experience taught and gained in this setting can be applied when a real-life event takes place.

Key to efficient transfer of skills that can be applied in an emergency situation is an accurate simulation of the interaction between humans, crane and spreader behaviour and environmental influences such as weather.

New Technology

The adoption of digital technology in the Port industry continues to gain momentum. From drone technology to monitor operations to increased use of cloud technology and the introduction of 5G networks, ports and terminals are becoming increasingly smart and connected.

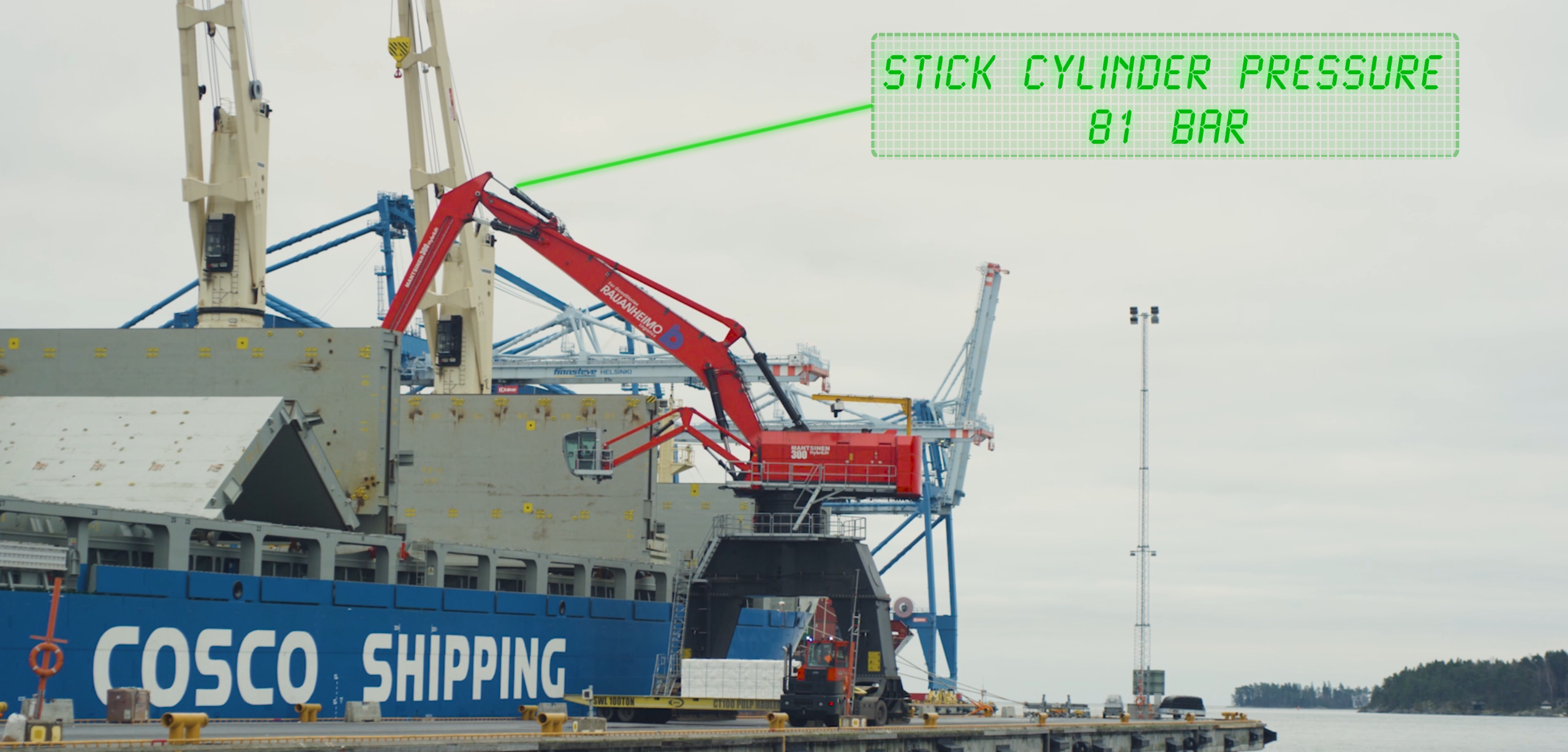

The same evolution is taking place in port crane and equipment operations. Sensors such as Time-of-Flight (TOF) distance scanners and LiDARs enable operator-assistance functions such as (boom) collision prevention, minimum distance control and precise container positioning. Improvements in connectivity and camera technology have enabled remote-controlled crane operations, which improve ergonomic and process productivity.

As human-machine interaction evolves and crane control systems become more intelligent, it is important for crane simulators to keep pace. It is not enough to approximate the behaviour of intelligent cranes; in order to offer operators a training environment that allows them to really adopt these new technologies, the simulator needs to be integrated with crane intelligence.

This means that operators can learn the full machine procedures, such as plant start-up, and get the exact same response from operator assistance and remote operations functions as in real life.

While these prevailing industry trends are setting new challenges to operator training, it is clear that novel approaches are needed to minimize the skills gap between training and real-life operations. Answering to the call, we at Mevea are developing Next-Generation Port Crane Simulators with capabilities unlike any other simulator in the industry. To find out more, contact us or read more on our ebook below.

Ready to learn more about next-generation simulation training? Check out our ebook!