2019 Simcenter Conference: an event dedicated to simulation, testing and design in all sorts of industries from aerospace to marine and beyond. Last week, hundreds of industry experts gathered to Amsterdam Mövenpick conference hotel to explore how different simulation methods together are bringing the Digital Twin concept to life.

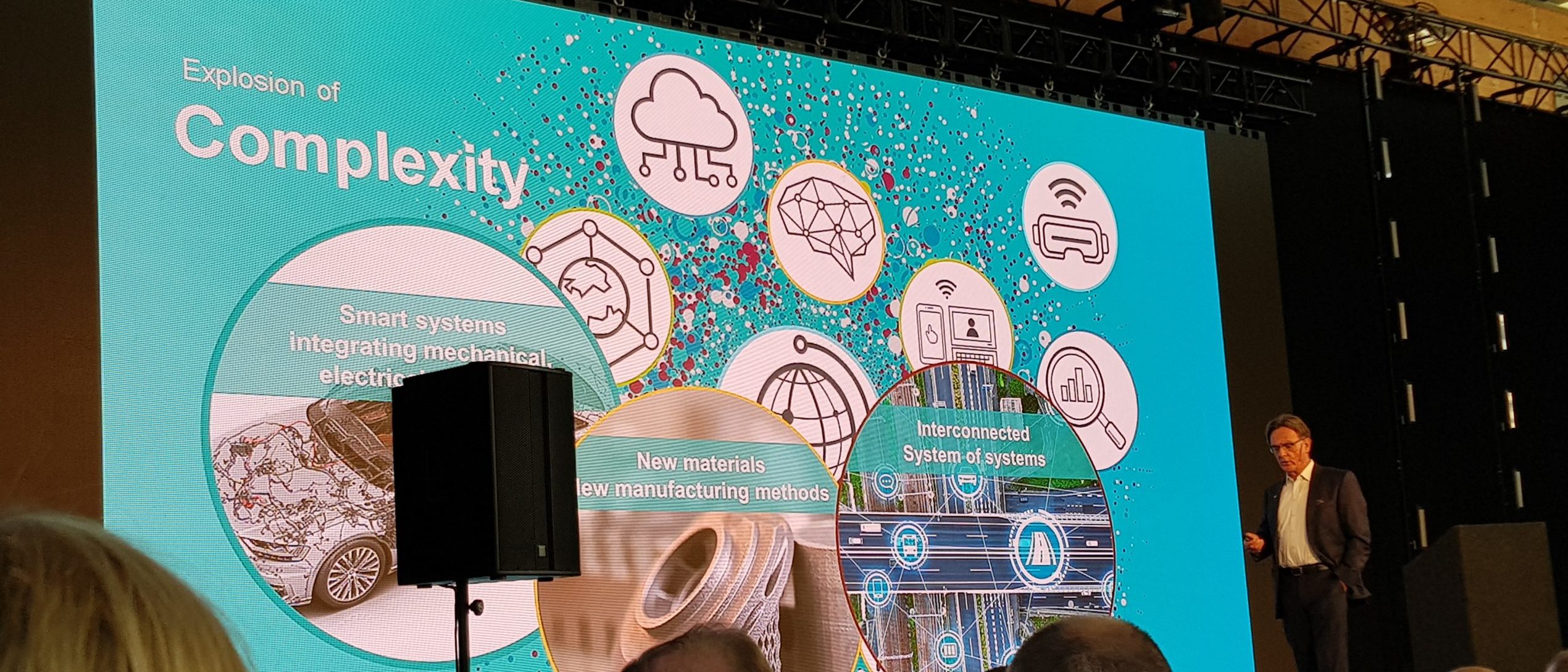

In the keynote presentation, Dr. Jan Leuridan (Senior Vice President, Simulation and Test Solutions at Siemens Digital Industries Software) addressed the explosion of complexity the designers, developers, and manufacturers are facing today. Not only are the ways of working changing, but the products themselves are on the verge of significant disruption. The amount of software going into machine intelligence these days is a very real and prevailing challenge – how to keep up?

One of the ways we at Mevea are addressing the issue is through cooperation with our partners, such as Siemens.

As a Siemens partner, we joined the event to demonstrate how physics-based Digital Twins can be easily built by simultaneously utilizing multiple software, each with their own, unique strengths. Through the Functional Mock-up Interface (FMI) co-simulation, we can couple the Mevea Product Development software with Simcenter Amesim to create the Digital Twin.

This way, for example, the product development team working on an excavator can simulate the hydraulics and powertrain of the Twin in Amesim and test and validate the design in the Mevea simulation environment with the real-time simulation of the full system including the mechanics, soil, sensors, control system and more.