Simulation

Solutions for

Product Development

Home » Solutions » Digital Twin » Product Development

Create and run fully functional virtual prototypes and digital twins with Mevea Simulation Solutions.

Take On the New Era of OEM Product Development with Mevea Simulation Solutions

Staying ahead of the competition is becoming increasingly difficult. With Mevea Simulation Solutions you can take your product development to the next level by utilising digital twins, virtual prototyping and by enabling interdisciplinary approach to engineering and testing.

Mevea Simulation Software is the leading tool for real world physics and real-time simulation.

Benefits of Mevea Simulation Solutions for Product Development

30%

Reduction in Product Development Lead Time

50%

Decrease in physical prototyping costs

90%

Reduction in PLC software implementation time

Autonomous Equipment

The development of autonomous equipment is a high priority for many. With Mevea Simulation tools you can test and train your equipment until they are ready for the production lines!

Watch Webinars:

How the World-Class Companies Stay Competitive in Autonomous & Assistive System Development?

Control System Integration With Physics-Based Digital Twin(s) In Product Development

Virtual Prototypes

Test your equipment in changing weather conditions.

Develop and test systems for recognising surroundings and traffic in a safe way.

Interdisciplinary Engineering

Create a development environment, where all your teams can work together from the beginning.

AI Training

Electrification

Shifting to electrically powered products usually requires a lot re-engineering and improvements to energy efficiency. Import your product designs and models to the most advanced physics engine and test environment on the market and speed up the electrification of your products!

Watch Webinars:

Digital Twins in Electrical Driveline Conceptual Design

Virtual Prototypes

Test different components and configurations to find out which electric or hybrid motors, generators, and batteries best suit your product.

Interdisciplinary Engineering

Create test environments that account for everything that plays a part in the operation of your products.

Energy Efficiency

Fine tune your products' energy efficiency by testing different configurations and discover ways to do more with less.

Product Development Optimisation

There is a lot to be gained from optimising your product development. Faster development lead times and decreased costs of prototyping will give a competitive edge.

Virtual Prototypes

Enable better product development with a prototype shared by all your teams.

Interdisciplinary Engineering

-

and faster product development.

Customer Centric Development

Involve your customers in the R&D process with the help of Mevea simulation tools.

Feedback Testing

Gain valuable insights about your prototype and develop better products.

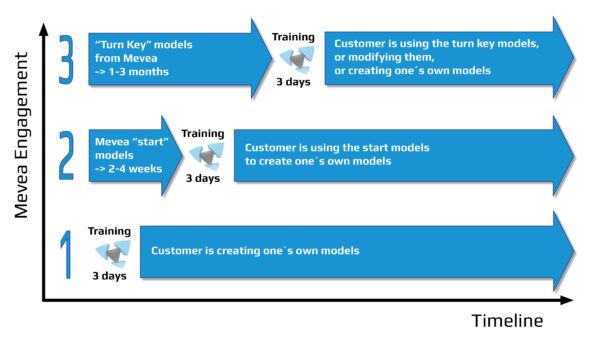

How To Get Started

Itching to start creating your own virtual prototypes and digital twins? We offer three options to get you on your way.

All the options include three days of training to get you and your team familiarised with the software.

Turnkey Models

Focus on what is important.

Mevea will provide you all the models you need to start creating your own virtual prototypes and digital twins.

Delivery time 1-3 months

Start Models

Get a head start.

Mevea will provide you with generic Start Models, that you can modify and customise to meet your specific needs.

Delivery time 2-4 weeks

Build Your Own Models

Do-It-Yourself.

Mevea will provide you all the tools and training you need to build your own models from scratch.

Available immediately

When A MiLLIsecond Makes All The Difference In The World

What You'll Get With The Most Advanced Physics Engine On The Market

1. Extremely realistic equipment behaviour based accurate physics simulation enables the best training simulator solution in the marketplace.

No costly surprises when moving from simulator to real equipment.

2. Crane specific controls and characteristics with accurate physics simulation and best-in-class training capabilities enable high skills transfer in simulator.

Faster productivity ramp-up in real equipment.

3. We aim for long term partnerships with our customers. We want to understand your specific requirements, and provide the solutions that you truly need.

Commitment to support customer’s long term business objectives.

Mevea Software

The core of the Mevea Simulation Software is Mevea’s own physics engine, which accurately simulates the mechanics, hydraulics, power transmission and the operating environment of the machine. Click to read more.

Watch Mevea Virtual Seminar 2023 Replay

Mevea has delivered Digital Twins and Training Simulators to Siemens

Mevea Provides aRTG Training Simulator to Konecranes

How can Digital Twins be utilised in product development?

Learn more in our ebook.