Software for Real-Time Simulation

Real-Time Simulation with Real-World Physics

Mevea Simulation Software is an excellent real-time simulation tool for developers to test new features and designs of a working machine. The core of the software is Mevea’s own physics engine, which accurately simulates the mechanics, hydraulics, power transmission and the operating environment of the machine. Our physics engine is the most powerful available in the market today and the mathematical calculations behind the dynamics are scientifically proven.

With Mevea Simulation Software, you can build physics-based virtual prototypes and digital twins, capable of simulating your product behavior and use in real-time, and thus gain significant business benefits throughout the product lifecycle – something already proven in practice by many world-class companies.

Mevea Software Demonstration

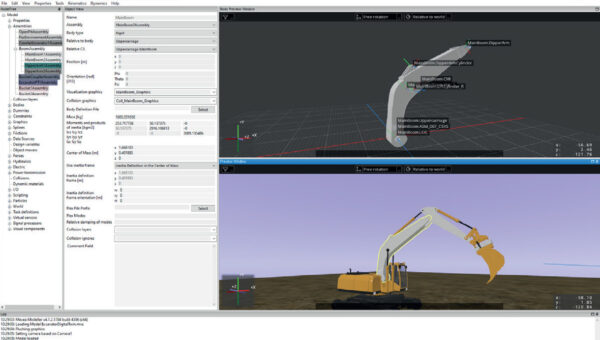

Mevea Modeller

- Create and edit virtual machine models and environments based on your existing assets

- Design mechanics, hydraulics and powertrain all on the same platform

- Digital twins include the environment, work process, and I/O interface to the machine control system (HIL – Hardware in Loop)

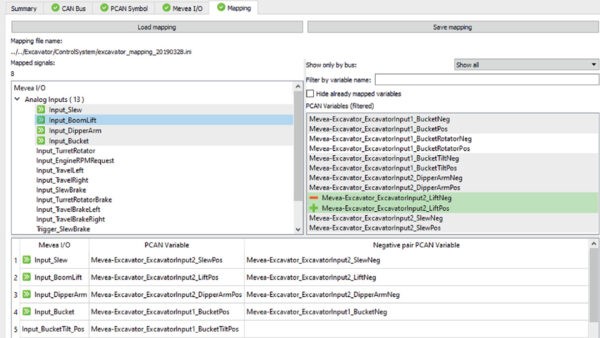

Mevea I/O Toolbox

- Connect all external systems to the simulation

- Machine control and automation systems

- Simulink® simulation models

- Motion platform and other hardware

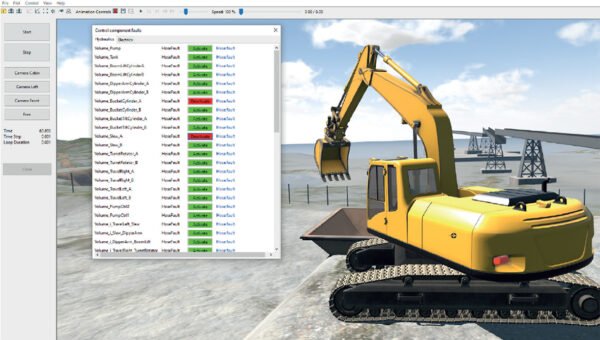

Mevea Solver

- Run your models in real time using Mevea simulation engine

- View and analyse the results of user-selected parameters

- Record the simulation for later review and research

Mevea Digital Twin Components

Mevea Simulation Software is the most advanced and precise software available that provides real-time simulation of heavy machinery and their surroundings.

Mevea real-time, physics based, digital twins consist of five main components:

Virtual Environment

The space where your machine operates. It can be outdoors or indoors or a combination of both. It may also include deformable soil areas to study the travelling capability of virtual machine.

You can choose from several standard virtual environments: sand pit, underground mine, forest, warehouse and port. Environments and conditions can also be tailored to your specifications (e.g. your port layout, time of day and weather changes, like hard rain or wind effects on a ship and crane wires).

Virtual Sensors

You can equip your virtual prototype or digital twin with virtual sensors such as pressure, displacement, velocity, acceleration, etc.

More advanced sensors, like LiDAR, camera, GPS, odometers and IMU are also available. Sensor output mimics the real sensor signal and protocol.

Virtual Work Process Model

Work process model defines the interaction between your machine and the targets it manipulates. Mevea Simulation Software comes with a wide range of standard work process models.

One of the unique and field proven Mevea capabilities is deformable soil which can be used e.g. with buckets, tyres and tracks. You can also create or integrate custom work processes.

Virtual Machine Model

Your virtual prototype or digital twin will have the same components as the eventual physical machine, e.g. mechanics, power train, tyres, crawlers, hydraulics, control signals of components.

We also provide generic virtual machine models.

Interface to Control System

Control system software and hardware are connected via physical connection like CAN or CANOpen bus or socket connection

What sets Mevea Simulation Software apart?

The next level of accuracy

The accuracy of the real-time simulation depends on how rapidly the smart sensor data from the physical counterpart (assets, processes and environments) is continually collected and processed to the virtual duplicate (digital twin) for the virtual recreation update. Reaching perfection requires exceptionally high computing powers. Mevea Software’s data collecting cycle times are the fastest on the market, which verifiably makes Mevea simulations’ quality second to none.

First-class integration with any existing systems

OEMs often use co-simulation in their prototype product development, which is a joint simulation of loosely coupled stand-alone sub-simulators. The integration of Mevea software to ANY existing systems for co-simulation is the fastest and most reliable in the market. As proof, we highly recommend starting a pilot program with Mevea.

How Mevea Simulation Software works?

Modelling and simulating

In the modelling stage, you build the simulation model the same way as in most CAD software.

You bring the mass and inertia data from the CAD model for creating the machine bodies. Then you attach these bodies to each other using different constraints and joints. Next you add the hydraulics, as well as the engine and the power transmission.

Bodies can be simulated also flexible, and the implementation of friction curves between objects is easy.

Real-time results

After you’ve set the parameters, you can run the real-time simulation instantly. Mevea Simulation Software will provide accurate real-time data both during the simulation that you can export for later examination.

You can plot data, for example, of:

- Body position and orientation

- Energy consumption

- Constraint forces

- Hydraulic pressures

- Collisions between bodies

Use your existing assets efficiently with Mevea Simulation Software

Mevea Software API and other interfaces enable several possibilities to connect to your existing development environment.

Using Mevea CAD interface numerical information related to dynamics simulation and visualisation graphics for real-time visualization can be produced directly from your CAD software like PTC Creo.

- Unity with Mevea assets for modelling and environment perception sensor models

- Unreal engine

Mevea physics simulation can be visualised via various graphics engines like Unity, using Mevea Unity API. Unity assets add the possibility to implement high-level visualization and use your Digital Twin for training and marketing purposes.

- CAN, CANOpen

- Socket connection

- Physical I/O via National instruments products

Mevea Unity visualisation supports Mevea’s realistic deformable soil behaviour. Mevea ROS and ROS2 interfaces enable the use of these development platforms with highly detailed Mevea Digital Twins.

- FMI 2.0 co-simulation master functionality

- Matlab/Simulink via synchronous TCP/IP connection

- Matlab/Simulink via asynchronous connection

- Scilab/Xcos via synchronous TCP/IP connection

What are the capabilities of Mevea’s simulation software?

How will it benefit your business? What can it do for your product development?

Download now to learn more about Mevea Software and how it can benefit your business across entire product lifecycles.