Technical Research Centre of Finland Ltd.

A leading research and technology company in the Nordic countries.

Virtual prototyping has typically decreased our end customer development lead time by 10-20%.

Kalle Määttä, Senior Scientist, Lifetime Management, Industrial IoT, Success story: VTT Technical Research Centre of Finland

Challenge:

How to develop and test advanced control system algorithms with real control system hardware/software and minimise the needed prototypes and the total lead time.

Solution:

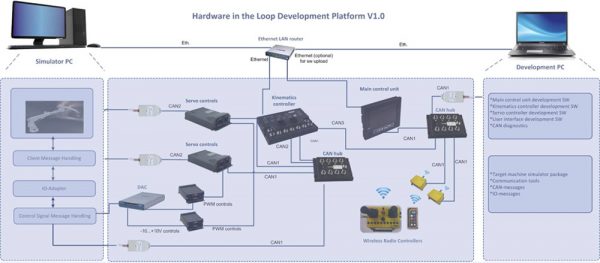

VTT decided to use Mevea’s real-time simulation software and services to create a virtual prototyping environment, including virtual machine operating in a realistic virtual environment and the real control software/hardware in the loop.

Benefits:

By working with virtual prototyping, VTT has gained the following benefits:

- Reduction of development time and costs

- Rapid development of control algorithms in a realistic environment

- Evaluation of advanced algorithms fast, safely and efficiently

- Efficient testing and optimisation of different structures, actuator systems, and control systems prior to manufacturing