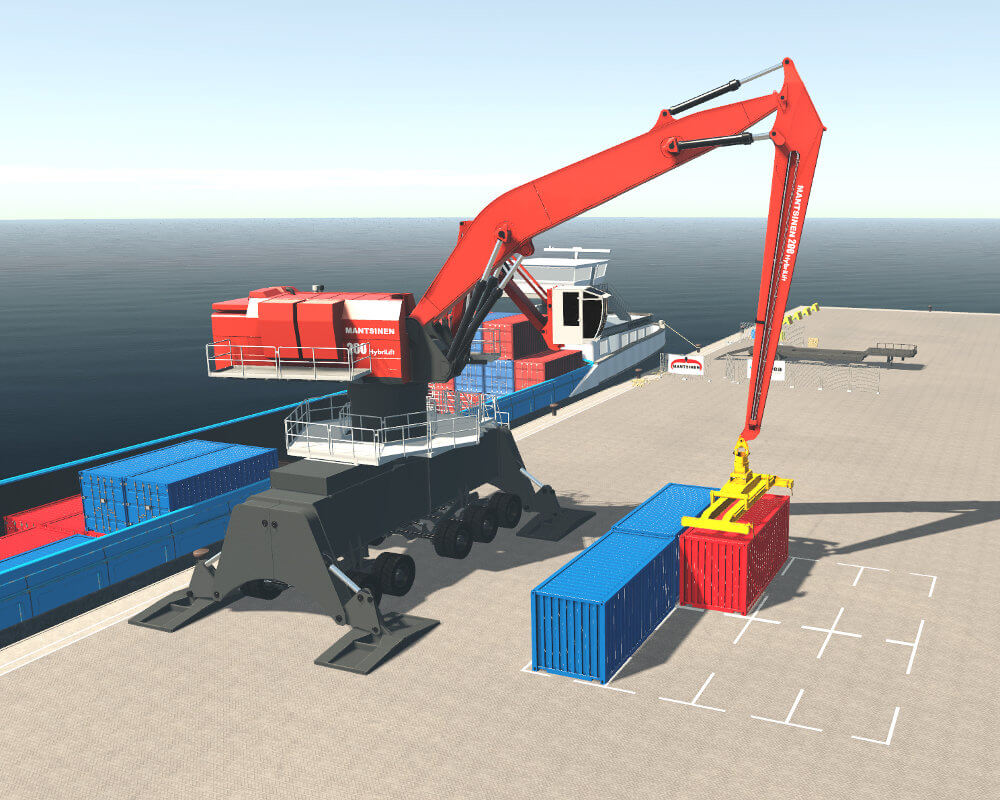

Mantsinen, a family-owned company, provides world-class material handlers and logistics services to its customers. In 2015 Mantsinen won the Crane of the Year Award at the IBJ Awards in Antwerp, Belgium, for its 200 M HybriLift® hydraulic mobile harbour crane.

With the simulator we are able to serve our customers better, whether the question is faster development of customized solutions or operator & service personnel training.

Mia Mantsinen, Vice President, Success story: Mantsinen Group Ltd.

Challenge:

How to develop customized material handling solutions quickly and cost-effectively? How to train operators to perform their job efficiently and safely by using Mantsinen solutions in the best possible way?

Solution:

Mantsinen decided to use custom-built simulators from Mevea to cover their processes end-to-end, i.e. the same simulation model is used for product development, sales/marketing, and -training purposes. Realistic machine behaviour is the key for Mantsinen, hence the simulator includes real machine control hardware and software integrated with the virtual machine, environment and work process simulation.

Benefits:

With the simulator, Mantsinen has been able to virtually develop and test new machine features and capabilities. This has shortened the R&D and engineering processes and made them more cost-efficient. In addition, they have used the simulator for operator and service training with good results. This has resulted in surge in demand for training services and a positive word-of-mouth within the sales and customer networks.