A leading global supplier of equipment and tools, service and technical solutions for the mining industry.

Virtual validation makes it possible to accept product solutions at the early stage without any physical prototypes.

Arto Vento, Lead Structural Engineer, Success story: Sandvik Mining

Challenge:

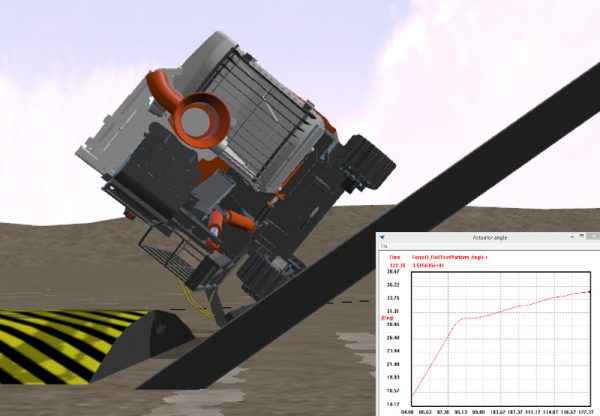

To enhance product quality and performance and at the same time decrease product development lead time and cost, Sandvik wanted to develop virtual product validation in the early design stages. The ultimate goal was to have a working virtual prototype which could be used for customer validation before the end of concept design stage.

Solution:

Sandvik decided to use Mevea Simulation Software and services globally to develop virtual prototyping.

Benefits:

With working virtual prototypes, including real-time hydraulics simulation, Sandvik has been able to increase product understanding during the concept stage and replace some physical tests like machine dynamic stability with virtual testing.