Discover Mevea’s New Training Simulators and Their Unique Benefits at TOC Europe 2023

June 6, 2023

TOC Europe 2023 will be organized 13-15 June in Rotterdam, Netherlands. Mevea will be demonstrating new training simulators for remotely and cabin operated port cranes. ...

Read More

Portable Remote Training Simulator

September 28, 2021

There is one irrefutable truth in personnel training – money can buy great training tools, but finding great instructors isn’t as easy. When you send ...

Read More

Turnkey Digital Twin

April 7, 2021

Creating a Digital Twin may seem complicated, but it is not. While implementing physics-based real-time simulators in your trade show arsenal can yield significant advantages ...

Read More

Maximising Event ROI – Bauma 2022

March 31, 2021

Investing in a trade show often means investing in space. Your return on investment depends on how many potential leads you generate during the event. ...

Read More

Standing Out in Bauma 2022

March 24, 2021

All key players. All innovations. All target groups. All trends. Gigantism is a word that bauma uses to describes the biggest live trade shows of the ...

Read More

Three lessons we learned from implementing 100+ Digital Twin projects

August 28, 2019

We have been helping innovators and industry leaders to implement over 100 Digital Twin projects in industries such as Construction Equipment, Mining, Ports & Logistics ...

Read More

Increasing Port Safety through Next-Generation Crane Simulators

July 9, 2019

How do we prevent accidents with port cranes from happening? The short answer: operator training and preventive technology. These both can be developed further and ...

Read More

Operator Training: Keeping Pace with the Port Industry

July 1, 2019

The port industry has a history of innovating to meet the changing requirements of global shipping and trade. However, as cranes are becoming smarter and ...

Read More

Digital Twins enabling IIoT Machines

June 4, 2019

While the pace of technology development in the heavy machinery industry accelerates, manufacturers continue to face demands for increased productivity and design complexity to meet ...

Read More

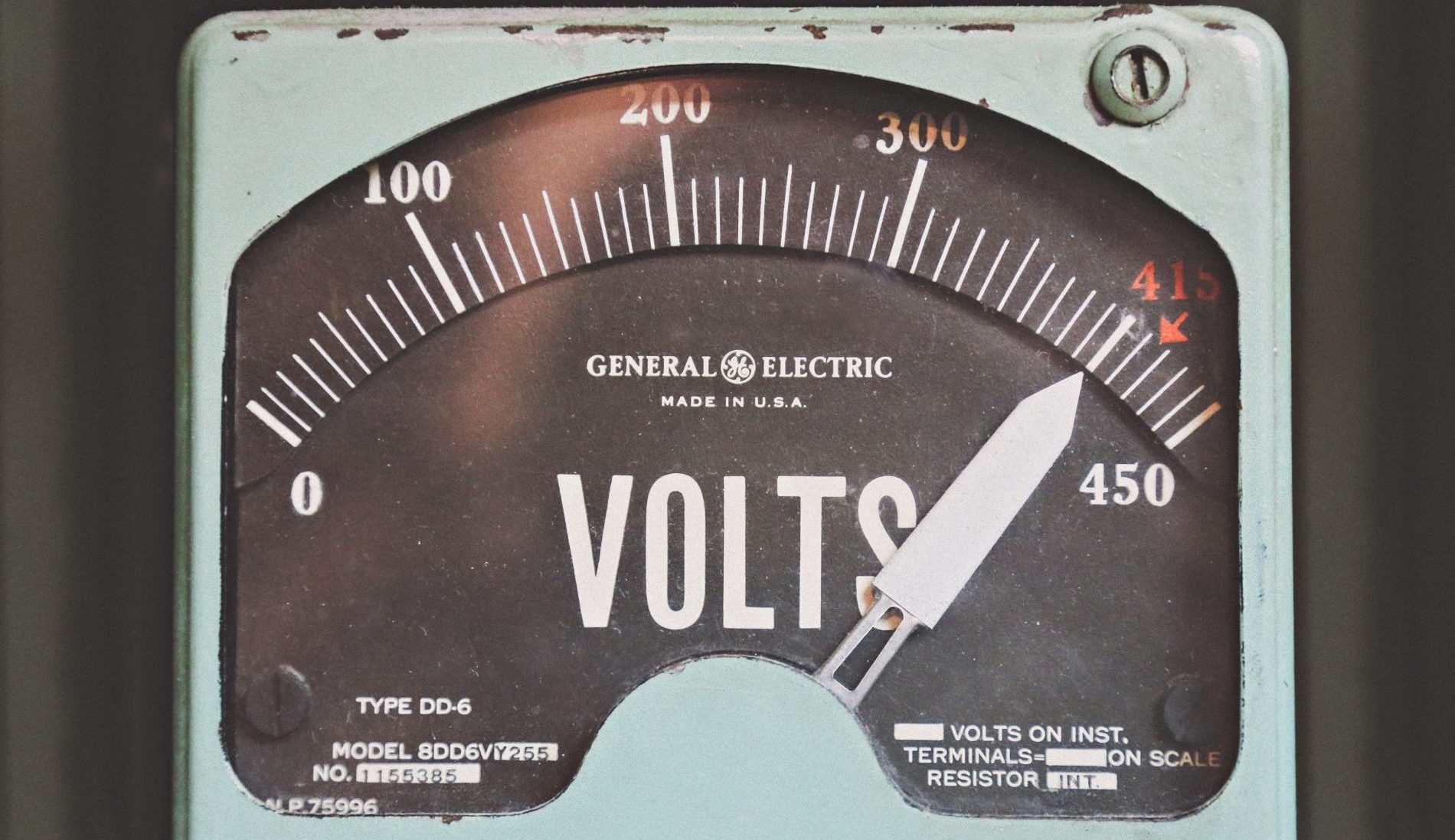

It’s Electric: Physics-Based Digital Twins Powering a Green Revolution in the Construction Industry

March 25, 2019

In its Bauma industry barometer, Messe Munchen said that 32% of survey respondents rated "Research into machines and vehicles with electric drive systems" as most ...

Read More

The Digital Twin Journey: A Smooth Pathway to Digital Innovation

February 27, 2019

How do you go about achieving the promise of Digital Twins while at the same time safeguarding the substantial investments made in people, technology and ...

Read More

Accelerating intelligent machine development and operation: Digital Twin and AI

November 29, 2018

Although more and more products and devices are connected, data being produced within the IIoT might not have the quality and coverage needed to reliably ...

Read More