Watch Mevea Virtual Seminar 2023 Replay

September 15, 2023

Mevea’s 10th anniversary Virtual Seminar “How the World-Class Companies Stay Competitive in Autonomous & Assistive System Development?” was streamed live on October 17th 2023. This ...

Read More

Watch the Webinar Replay: How to Boost Port Crane Operator Performance

March 3, 2023

The webinar replay explores the current container terminal challenges related to operator training and automation development of the cranes and how the digital twin based, ...

Read More

Watch Mevea Tech Talk, Ep. 5, Replay

November 28, 2022

The fifth episode of highly popular webinar series of Mevea Tech Talk was streamed live on November 24th. This time we introduced how to combine ...

Read More

Watch Video Recording of Mevea Online Seminar 2022

November 23, 2022

The 9th annual Mevea Seminar 2022, streamed live on October 19, was a success. The objective for this year´s seminar was to introduce what benefits ...

Read More

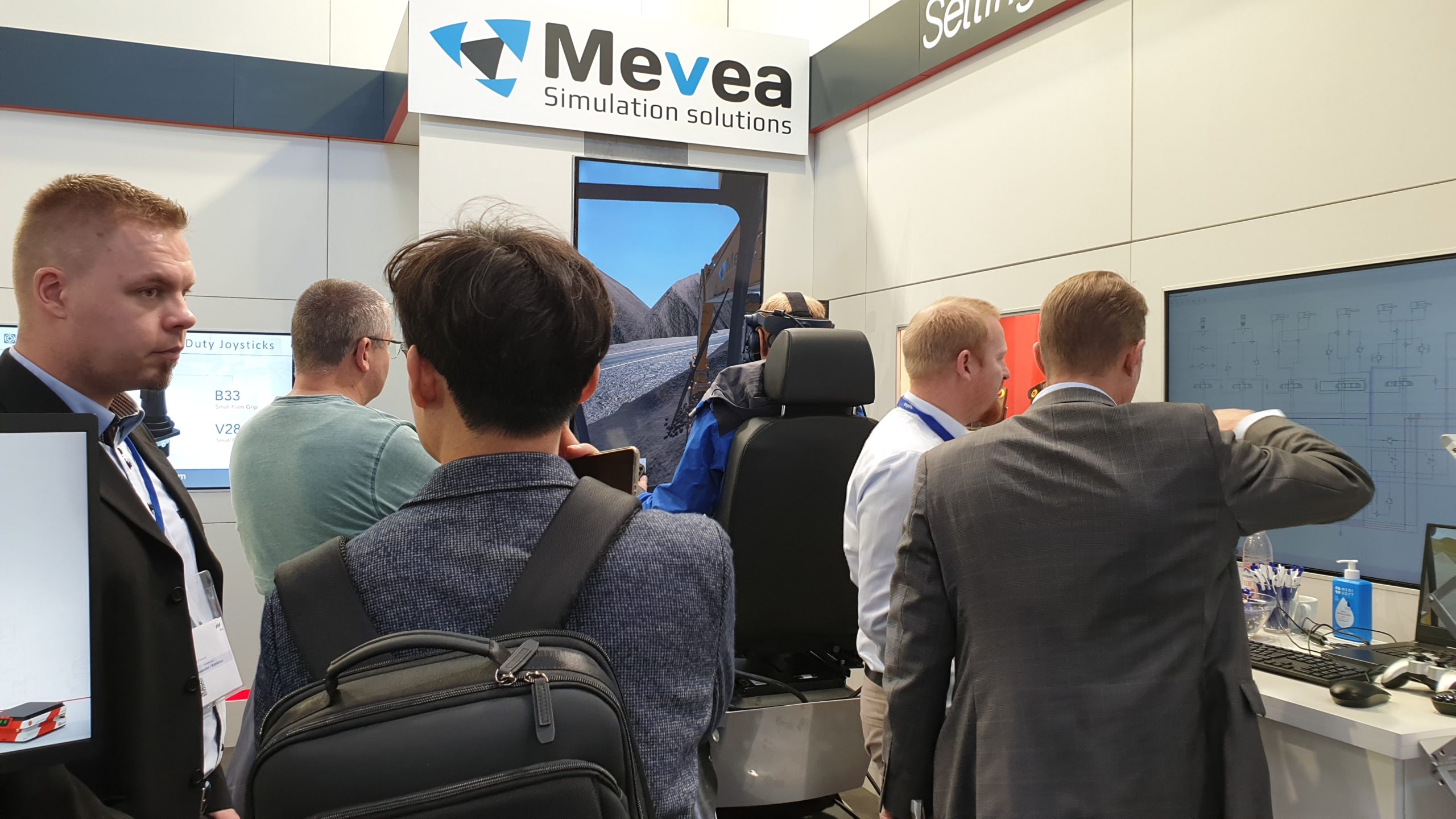

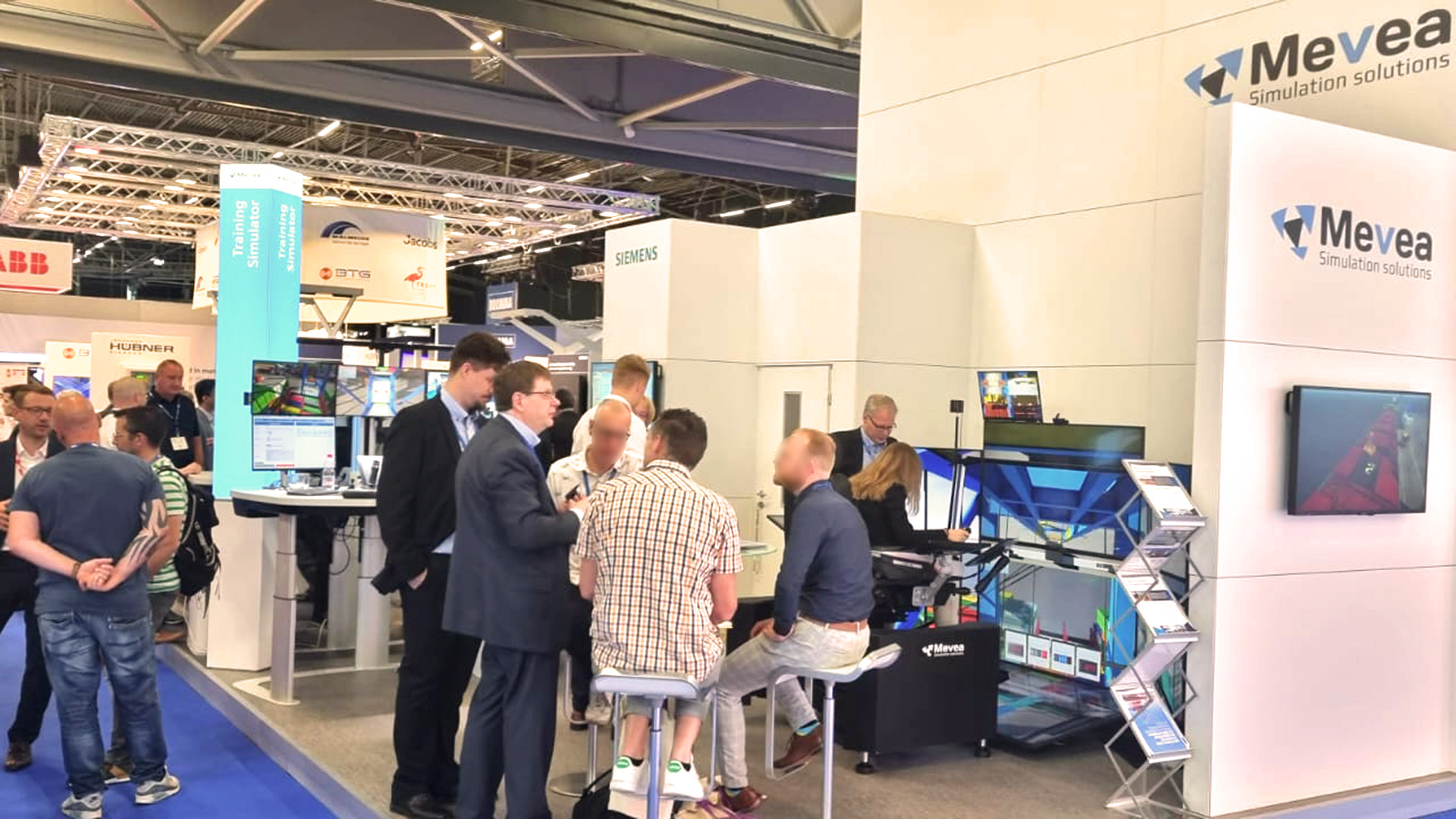

Mevea and Bauma 2022 – Together on the same page

November 18, 2022

It´s time to peek back and recapitulate the full week of 33rd edition of the world’s leading trade fair for building industry. At the end ...

Read More

Mevea Online Seminar 2022:

Learn the Concrete Benefits of Physics-Based Digital Twin in Development and Testing of Intelligent Machines

September 23, 2022

Welcome to the 9th annual Mevea Online Seminar 2022, which will be organized as a virtual event. Traditional product development and testing approaches do not ...

Read More

Wärtsilä and Mevea Signed a Strategic Supply and Purchase Agreement for Crane Training Simulators

April 4, 2024

Wärtsilä and Mevea have strengthened their simulation cooperation by signing a Strategic Supply and Purchase Agreement (SSPA). The global agreement covers port and ship crane ...

Read More

Wanted: A Senior Sales Manager / Sales Executive for Mevea!

March 27, 2024

Are you looking for a new opportunity in your career, where you can work with the global market, be part of the team that ...

Read More

Mevea on Stage at 2nd Autonomous Off-Highway Machinery Summit

February 28, 2024

Mevea joined the 2nd Autonomous Off-Highway Machinery Technology Summit which took place in Munich, Germany, on February 21-22, 2024. The summit served as a platform ...

Read More

Use of Digital Twins to Smooth the Implementation of STS Crane Automation: Bridging the Gap Between Technology, Process, and People

August 29, 2023

In the dynamic domain of container terminals, Ship-To-Shore (STS) cranes play a pivotal role, directly influencing the overall efficiency of a container terminal. With the ...

Read More

Mevea Has Delivered Heavy Equipment Training Simulator to Tegeta Academy

July 6, 2023

Mevea has delivered a heavy equipment training simulator to Tegeta Academy in Georgia. Simulator will be used as part of extensive heavy equipment operator retraining ...

Read More

High Interest on Mevea Solutions for Automated & Semi-Automated Crane Development and Training

June 30, 2023

Mevea simulator’s accuracy and functionality supporting both assistive & autonomous system development and advanced operator training raised lot of interest at TOC Europe 2023, where ...

Read More

Mevea has delivered Digital Twins and Training Simulators to Siemens

June 9, 2023

Mevea has delivered digital twins, simulation software and training simulators to Siemens. Siemens integrates these solutions within its open and modular SIMOCRANE Remote Control Systems ...

Read More

Mevea Provides aRTG Training Simulator to Konecranes

June 9, 2023

Konecranes has ordered an Automated Rubber Tired Gantry (aRTG) crane training simulator from Mevea. The simulator will be integrated with Konecranes crane PLC and Remote ...

Read More

Discover Mevea’s New Training Simulators and Their Unique Benefits at TOC Europe 2023

June 6, 2023

TOC Europe 2023 will be organized 13-15 June in Rotterdam, Netherlands. Mevea will be demonstrating new training simulators for remotely and cabin operated port cranes. ...

Read More